New Bio-Based Barrier Coating Sets Benchmark for Sustainable Packaging

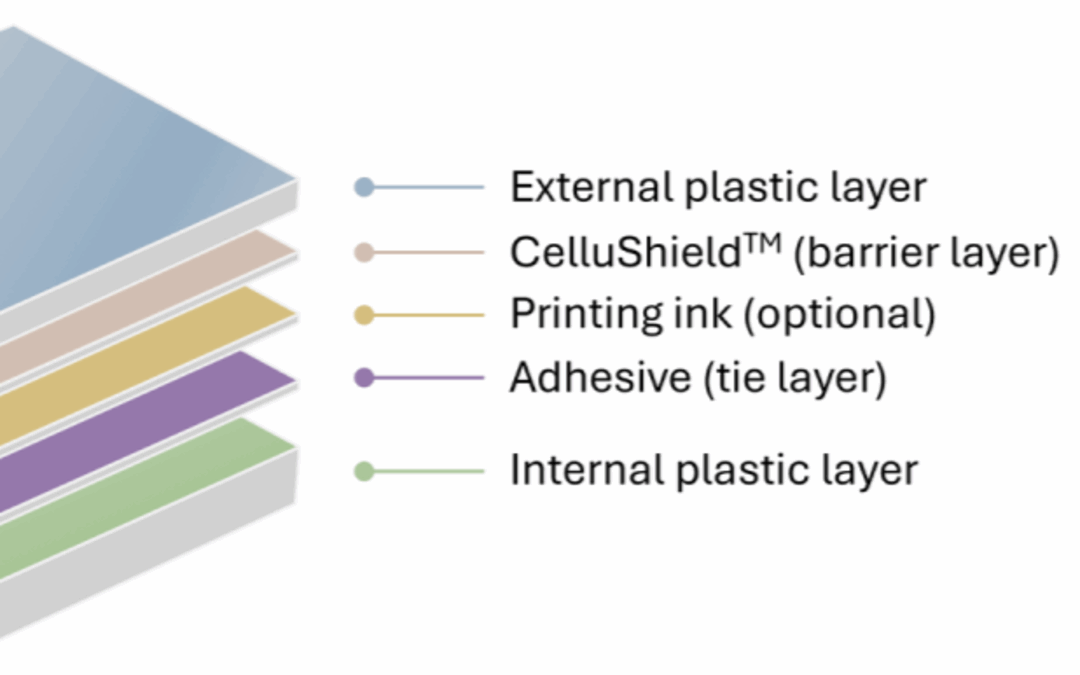

CelluForce unveils CelluShield, a cellulose-based barrier coating advancing sustainable packaging for food and pharma sectors.

Canadian biomaterials company CelluForce unveiled CelluShield, a cellulose-based barrier coating, on Monday.

This coating promises to enhance recyclable, flexible packaging without compromising performance, marking a significant step forward in sustainable packaging innovation.

The water-based coating, made from renewable cellulose, offers strong resistance to oxygen and moisture while enabling mono-material structures that can be recycled through existing streams.

“Brand owners and converters no longer need to choose between performance and recyclability,” said CelluForce CEO Sébastien Corbeil in a statement. “With CelluShield, we are offering a practical solution that protects products, lowers carbon footprint, and simplifies recycling.”

The company stated that the coating meets stringent food safety standards, is free from harmful chemicals, and aligns with the extended producer responsibility requirements in Europe.

Canadian Innovation in Sustainable Packaging

The development of CelluShield was carried out with FPInnovations and funded by Natural Resources Canada’s Transformative Technology Program. Support also came from the National Research Council of Canada Industrial Research Assistance Program.

CelluForce emphasized that these collaborations highlight Canada’s leadership in driving innovation in sustainable packaging solutions.

Benefits Across the Value Chain

CelluShield is designed for use in food, pharmaceuticals, and other sensitive products. It can be applied through standard reverse gravure coating and lamination technology, making it suitable for polyethylene, polypropylene, and PET films.

Converters gain a turnkey path to recyclable structures without costly retooling, while brand owners can meet 100 percent recyclable packaging targets.

Consumers, meanwhile, benefit from safer and more sustainable packaging that extends product shelf life.

Supporting a Circular Economy

By replacing multilayer laminates with a recyclable alternative, CelluShield strengthens efforts to reduce waste and support circular economy goals.

The product is available as a ready-to-use coating or as a precoated film for easier supply chain adoption.

Founded in 2010, Montreal-based CelluForce operates the world’s largest cellulose nanocrystals plant, producing 300 tonnes annually. Its shareholders include Domtar, SLB, Suzano, FPInnovations, and Investissement Quebec.

Also Read:

Health Ministry Launches National Drive Toward Sustainable Food Packaging

Nirmal Menon

Related posts

Subscribe

Error: Contact form not found.