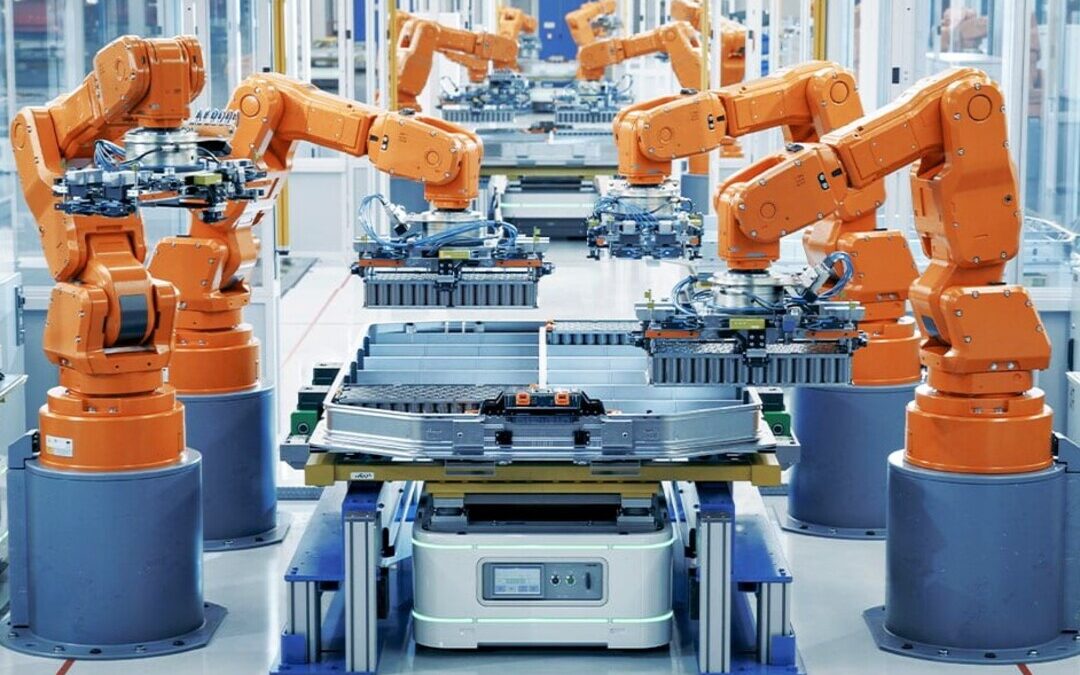

AI, Sustainability Push Global Manufacturers Toward Adaptive Models: Report

Manufacturers adopt adaptive models to boost sustainability, cut waste and strengthen supply chains, Tech Mahindra report finds.

Global manufacturers are embracing adaptive manufacturing to reduce waste, boost efficiency, and improve resilience, according to a new report from Tech Mahindra, which states that sustainability is becoming central to industrial strategy.

“The convergence of disruptive technologies, shifting consumer expectations, and the imperative for sustainability is reshaping the very foundation of industrial operations,” said Manikantan NS, senior vice president and global head of manufacturing at Tech Mahindra. “In this context, adaptive manufacturing emerges not as a choice, but as a strategic imperative.”

The report, “The New Era of Adaptive Manufacturing,” surveyed 690 senior executives worldwide and found that 98 percent of companies are implementing sustainable manufacturing practices. Artificial intelligence is emerging as a key enabler, with more than half of respondents using AI to optimize energy use and resource efficiency.

Sustainability at the Core

Operational efficiency was the most common driver of sustainable initiatives, cited by 59 percent of companies, while 51 percent pointed to brand reputation and 50 percent to regulatory compliance. Nearly half said reducing costs and waste was a priority.

Larger manufacturers reported stronger results from sustainability investments. More than half of firms with revenue above $10 billion reported cutting waste and costs, compared with less than half among smaller players.

“Adaptive manufacturing is about embedding sustainability and human-centric innovation into every layer of the value chain,” Manikantan said.

AI Powers Green Shift

AI is now the top technology supporting sustainability efforts, outpacing the Industrial Internet of Things and cloud computing. Fifty-three percent of firms reported using AI for energy and resource optimization, while 48 percent are deploying intelligent automation to reduce emissions.

For larger enterprises, AI adoption is even higher. Sixty percent of manufacturers with more than $10 billion in revenue use AI for sustainability, compared with 49 percent of mid-sized firms.

AI’s role extends beyond efficiency gains. By analyzing data on energy consumption, material flows, and waste generation, AI helps firms identify hidden inefficiencies and simulate the sustainability impacts across their supply chains.

Resilience and ESG Go Hand in Hand

Less than one in five firms described their supply chains as highly resilient. However, those allocating more than 15 percent of their IT budget to AI reported significantly stronger adaptability to disruptions.

Companies are also adopting cloud platforms for collaboration, blockchain for transparency and digital twins for scenario planning. These technologies are designed to lower risks from geopolitical tensions, raw material shortages and pandemics while aligning with sustainability goals.

“The resiliency to the supply chain is being really challenged at every level right now,” a Tech Mahindra manufacturing lead said in the report.

Costs, ROI and Integration Challenges

Despite the momentum, high upfront costs continue to be a stumbling block. Forty-one percent of respondents stated that implementation costs are a barrier, while 37 percent cited integration complexity, and 34 percent pointed to skills shortages.

Return on investment is another concern. More than a third of companies said they struggle to measure ROI from Industry 4.0 and adaptive initiatives.

“How you land the ROI is always a big debate. There are no defined templates, no defined guidelines,” Manikantan said.

People and Partnerships

Alongside technology, workforce skills are central to sustainable transformation. Two-thirds of respondents said advanced technologies such as AI and 6G are essential, but nearly as many emphasized upskilling staff to use them effectively.

Ninety-one percent of companies reported collaborating with suppliers on adaptive initiatives, indicating that ESG priorities are expanding beyond individual firms to encompass entire value chains.

Future Outlook

Tech Mahindra described adaptive manufacturing as a “blueprint for future-ready enterprises,” one that combines agility, intelligence and sustainability.

It stated that the most successful firms are applying adaptive principles across their supply chains, aligning ESG commitments with profitability, and utilizing AI to bridge gaps in efficiency and resilience.

“The future belongs to those who can transform with purpose, scale with intelligence, and lead with resilience,” Manikantan said.

Nirmal Menon

Related posts

Subscribe

Error: Contact form not found.