Researchers Upcycle PET Plastic Into Efficient CO2 Capture Technology

Danish scientists upcycle plastic waste into BAETA, a new material designed for efficient carbon dioxide capture and reuse.

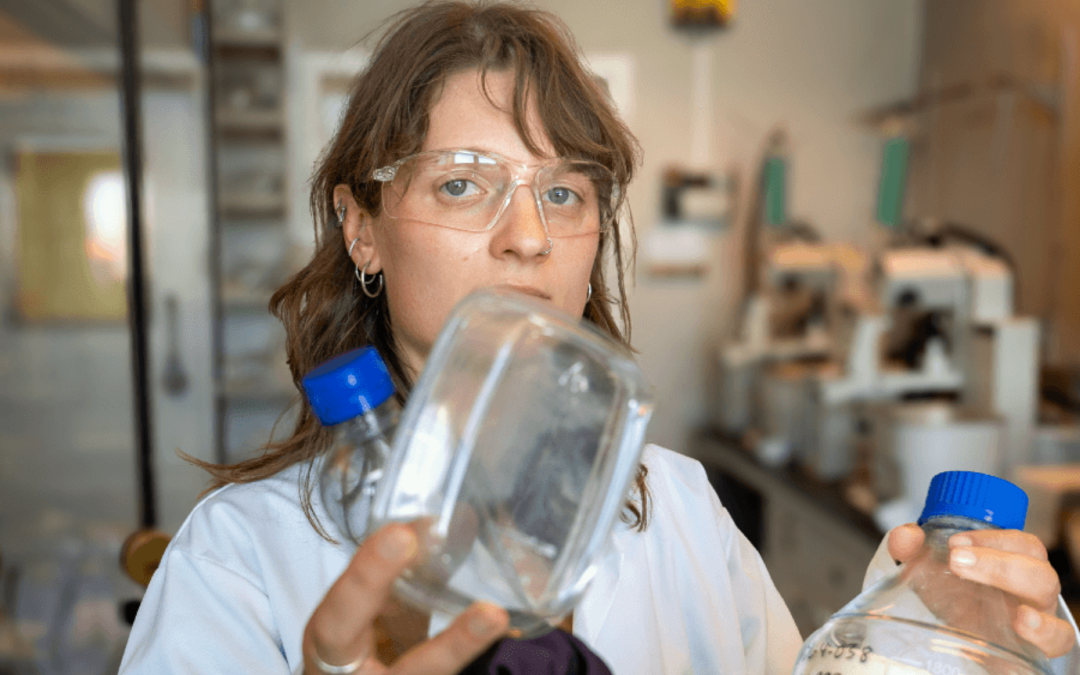

Chemists at the University of Copenhagen have developed a method to convert plastic waste into a new material capable of capturing carbon dioxide, offering a potential dual solution to plastic pollution and climate change.

The researchers have created a chemical process that transforms discarded polyethylene terephthalate, one of the world’s most widely used plastics found in bottles, textiles and packaging, into a carbon capture material called BAETA.

The material, described in the journal Science Advances, has a powdery structure that can be pelletized and installed in industrial plants to filter emissions.

“The beauty of this method is that we solve a problem without creating a new one,” said Margarita Poderyte, lead author of the study and a researcher at the university’s Department of Chemistry. “By turning waste into a raw material that can actively reduce greenhouse gases, we make an environmental issue part of the solution to the climate crisis.”

High Efficiency and Flexibility

BAETA is created by breaking down PET plastic into a chemical composition that strongly binds carbon dioxide. The process uses ethylenediamine, a compound known for capturing carbon.

Researchers said the new material compares favorably with existing carbon capture sorbents in efficiency while being gentler and more scalable.

The material can trap CO2 across a broad temperature range, from room temperature up to 150 degrees Celsius. Once saturated, it can be heated to release concentrated CO2 for storage or reuse in industrial processes.

“One of the impressive things about this material is that it stays effective for a long time. With its tolerance to high temperatures, it can be used at the end of industrial plants where the exhausts are hottest,” said Jiwoong Lee, associate professor and co-author of the study.

From Laboratory to Industry

The researchers say the next challenge is to scale up production of BAETA and prove its effectiveness outside the laboratory.

“We see great potential for this material, not just in the lab, but in real-life industrial carbon capture plants,” Poderyte said. “The next big step is scaling up to produce the material in tonnes, and we’re already working to attract investments and make our invention a financially sustainable business venture.”

They expect the first applications in factories where chimney exhaust gases could pass through BAETA units, stripping CO2 before release.

Ocean Plastic Potential

Large amounts of PET plastic end up in oceans, where they break down into microplastics that threaten marine life. The researchers stated that such degraded plastic is particularly suitable for their process.

“If we can get our hands on the highly decomposed PET plastic floating in the world’s oceans, it will be a valuable resource for us,” Poderyte said. “Our material can create a concrete economic incentive to cleanse the oceans of plastic.”

Concerns that the technology could undermine plastic recycling are unfounded, the team said. Instead, BAETA uses low-quality, colored or degraded PET that is unsuitable for traditional recycling.

“In principle, we could use new plastic for our method, but our target is PET plastic that is difficult to recycle,” Poderyte said. “So, this will be a collaboration rather than a competition with recycling.”

The project is supported by the Novo Nordisk Foundation CO2 Research Center and researchers from Aarhus University.

Nirmal Menon

Related posts

Subscribe

Error: Contact form not found.